Wipelot's Non-Motorized Equipment Tracking System , is the perfect solution for monitoring and tracking all types of towable and handheld non-motorized equipment, such as towable elevators, welding machines, generators, air compressors, tugboats, high-rise equipment, trailers, crushers, mixers, grinders, other aviation ground handling equipment, healthcare facility fixtures, etc. in indoor or outdoor large-scale areas such as construction sites, mines, airports, warehouses, healthcare facilities.

Wipelot's non-motorized equipment tracking systems contribute to increasing industrial operational efficiency, enhancing workplace safety, and reducing costs.

Wipelot, understands your needs and develops solutions around the world.

UWB 300.000+ Devices 1.000 km2 Mesh Indoor Network Area 100Mil+ Meter Traced Route

WHAT IS NON-MOTORIZED EQUIPMENT?

Non-motorized equipment can be defined as machines, tools, or vehicles that do not have an internal power source and need to be moved by pulling, pushing, or hand-carrying.

With the UWB (ultra-wideband) based Wipelot non-motorized equipment tracking system, you can easily monitor, analyze and evaluate the location of your equipment, thus increasing equipment and occupational safety.

How does it work?

The system is made up of battery-powered mobile tags that can be attached to equipment, zone readers that use UWB (ultra-wideband) technology, and Lotus RTLS software. Wipelot's wireless communication networks send data collected from tracked equipment in a given area to central or cloud-based servers, allowing Lotus to determine locations in real-time.

Precision: Because UWB technology provides highly accurate location information, it is possible to track non-motorized equipment in the field in real time.

Increased efficiency: UWB-based non-motorized equipment tracking systems help increase operational efficiency by reducing equipment downtime and allowing for faster recovery of lost, stolen, or broken assets.

Savings: Non-motorized equipment tracking systems based on UWB help deliver long-term cost savings by reducing the need for manual equipment checks and lowering the risk of equipment loss or theft.

Improved asset utilization: UWB technology's real-time monitoring capabilities provide valuable data on equipment usage, allowing industrial organizations to optimize equipment utilization and maintenance times, increasing overall operational efficiency.

SYSTEM COMPONENTS

Mobile Tags

Equipment UWB TAG

Equipment BLE Tag

Equipment BLE Tag

Anchor & Gateway

Industrial UWB Anchor

Indoor UWB Anchor

Industrial UWB Gateway

Indoor UWB Gateway

EagleEye Motion

EagleEye Sense

SOFTWARE

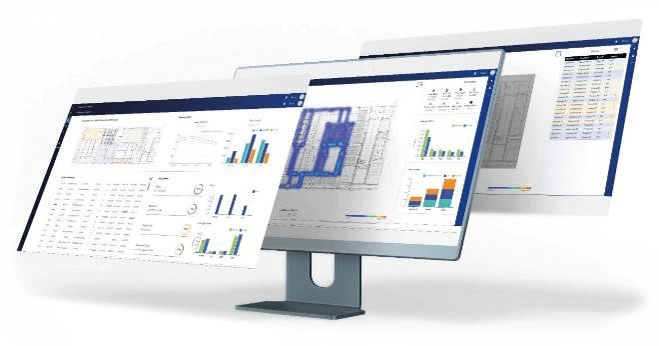

Wipelot's real-time location tracking software, Lotus, and the flow analysis and optimization module, Flow Analytics, elevate asset visibility and provide detailed insights into operational processes in facilities. This enables performance measurement for efficiency and helps mitigate potential risks in occupational safety.

Discover Related Success Stories

TEKFEN - Asset Location Tracking in Multiple Countries

Tekfen is among the leading construction companies, carrying out mega projects concurrently at multiple locations around the world. The number and functions of the motorized and non-motorized vehicles, passenger cars and personnel, used for the projects at different locations around the world, differ from each other.

Let's work together to find the

best solution

for your business needs

Wipelot is a member of Omlox, the UWB Alliance, and the FiRa Consortium, which unite tech companies that manufacture their own hardware and software systems, with a focus on UWB technology solutions. Wipelot has been recognized as one of the fastest-growing tech companies on the TOBB 100 and Deloitte Technology Fast 50 lists. It has also received numerous awards for its industrial IoT projects in both Turkiye and abroad.

Discover More RTLS Systems

Personnel Location Tracking

Wipelot Personnel Location Tracking System is an industrial integrated occupational safety system that lets you monitor the real-time location and movements of your employees and determine their precise location using UWB (ultra-wide band). This system makes a significant contribution to occupational safety by instantly monitoring your personnel within designated areas with sub-meter accuracy, shortening the time for immediate response in case of emergency.

Motorized Equipment Tracking

The Motorized Equipment Tracking System is an integrated equipment tracking and management system that can create multiple reports based on real-time data such as vehicle use and parking durations, fuel levels, speed violations, routes, facility entrance/exit information, and driver performance analyses by instantly tracking the motor vehicles in such places as airports, mines, construction sites, and warehouses.

Industrial Traffic Management

Signalization (traffic management system) is an award-winning (2019 RIFD Journal) occupational safety and efficiency system developed to prevent data loss and occupational safety risks arising from dense traffic created by motor vehicles in industrial settings such as mines, production facilities, and warehouses.

UWB Asset Tracking Over Wi-Fi

EAGLEEYE is the first UWB module integration for the CISCO AP IW6300 and 91xx series. It provides powerful Wi-Fi 6 connectivity as well as high-precision geolocation data at the same time, meeting facilities' digital transformation needs in operational efficiency and occupational safety through a single infrastructure.