The Crane Positioning and Safety System is an advanced crane safety system developed by Wipelot to prevent crane collisions, heavy machinery, and personnel from dangerously approaching each other. It is specifically designed to prevent accidents in industrial facilities, particularly during overhead crane operations and in areas beneath cranes. This crane positioning system uses Ultra-Wideband (UWB) technology for crane position tracking and collision avoidance, ensuring the highest workplace safety standards. It also offers additional modules to enhance operational efficiency.

UWB

(Ultra-wideband)

Crane Deceleration or Stopping

Easy Installation

Long Battery Life

(mobile tags)

Minimum Hardware Requirements

TOP INDUSTRIES

Why Does Crane Safety Matter?

Crane safety includes technological solutions and safety measures that ensure overhead cranes operate securely in industrial environments. Since crane accidents can cause severe injuries, financial losses, and operational disruptions, ensuring a safe working environment is vital for both employee health and productivity.

The Wipelot Crane Positioning and Safety System is specifically designed to prevent workplace accidents, enhance safety, and minimize equipment damage.

Enhance Workplace Safety and Operational Efficiency with Near-Zero Infrastructure and Easy Installation

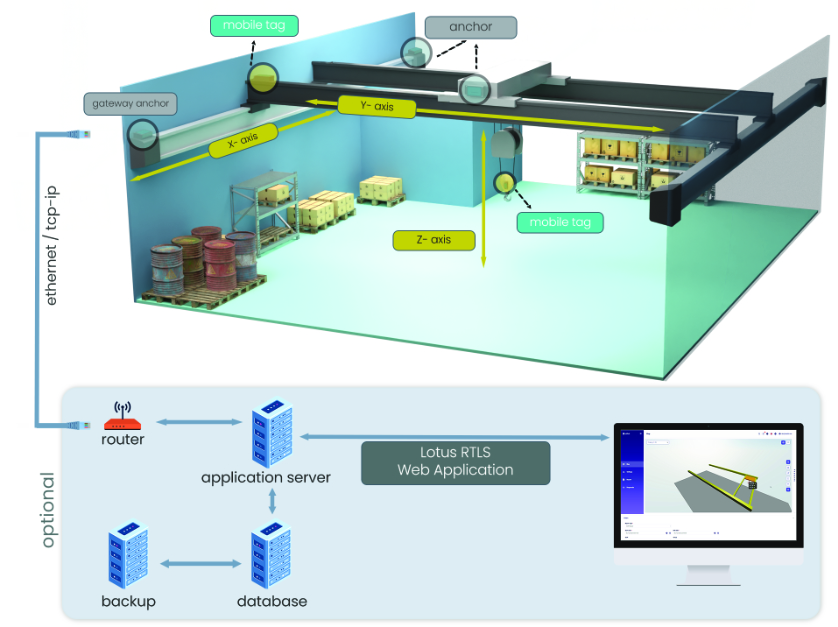

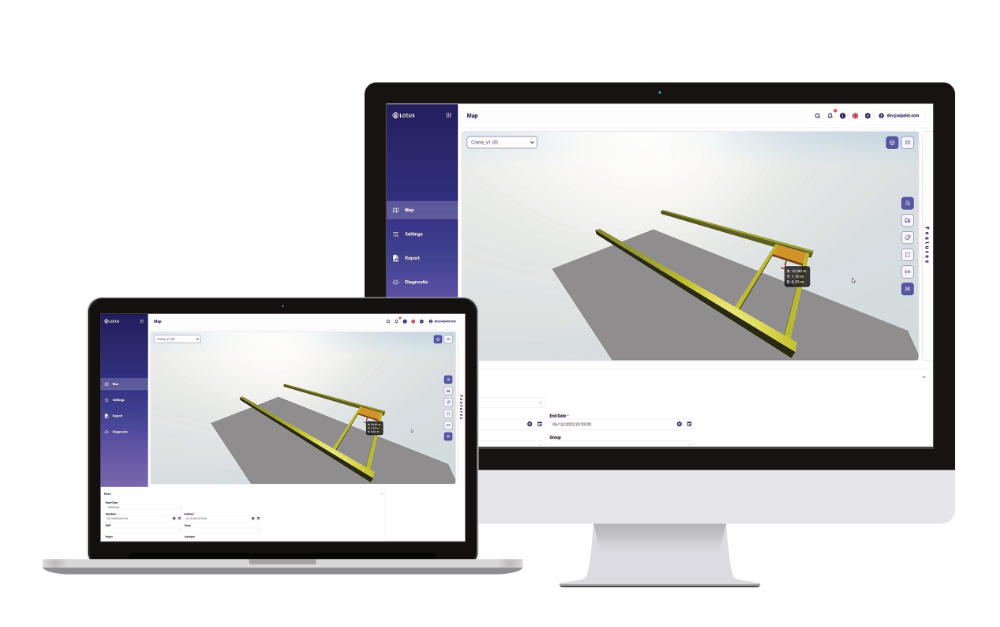

How does the Crane Positioning and Safety System work?

The Wipelot Crane Positioning System leverages a precise Real-Time Location System (RTLS) based on Ultra-Wideband (UWB) technology. This overhead crane anti-collision system ensures maximum safety by offering real-time distance monitoring between cranes, equipment, and personnel with high accuracy.

Key Features of the Crane Positioning and Safety System

Benefits of Implementing Wipelot’s System

CORE SYSTEM COMPONENTS

Anchor & Gateway

Industrial UWB Anchor

Industrial UWB Gateway

EagleEye Sense

Mobile Tags

Equipment UWB Tag

UWB Tag

Discover Related Blogs

Industrial Crane Safety and Positioning with RTLS

The key to improving crane safety and efficiency is RTLS technology! Wipelot's innovative systems elevate workplace safety in heavy industry. With precise positioning, real-time tracking, and integrated solutions, make your operations more secure and efficient

Let's work together to find the

best solution

for your business needs

Wipelot is a member of Omlox, the UWB Alliance, and the FiRa Consortium, which unite tech companies that manufacture their own hardware and software systems, with a focus on UWB technology solutions. Wipelot has been recognized as one of the fastest-growing tech companies on the TOBB 100 and Deloitte Technology Fast 50 lists. It has also received numerous awards for its industrial IoT projects in both Turkiye and abroad.

Discover More RTLS Systems

Lone Worker Safety

The Wipelot Lone Worker Safety System is an electronic occupational safety system that allows for real-time monitoring of the condition and position of workers working in hazardous settings, eliminating the need for communication equipment like as radios or phones.

Forklift Safety & Tracking

Wipelot Safezone is an approach and collision warning system developed for construction machinery. It is designed to prevent dangerous approaches and collisions between vehicles that are in motion throughout the day such as construction machinery, forklifts, reach trucks, or milk-run vehicles with each other, equipment, and personnel. Safezone plays an important role in occupational safety by creating a safe approach distance for vehicle operators working under difficult conditions due to layout, vehicle traffic in the working environment, many walking personnel, blind spots, and time pressure.

Social Distance Tracking - SDS

The Social Distance Monitoring and Warning System developed by Wipelot helps establish a safe and isolated working environment in accordance with the social distance rules to combat the COVID-19 pandemic. The COVID-19 pandemic has directly affected 180 million people since the day it started and caused close to 4 million deaths.