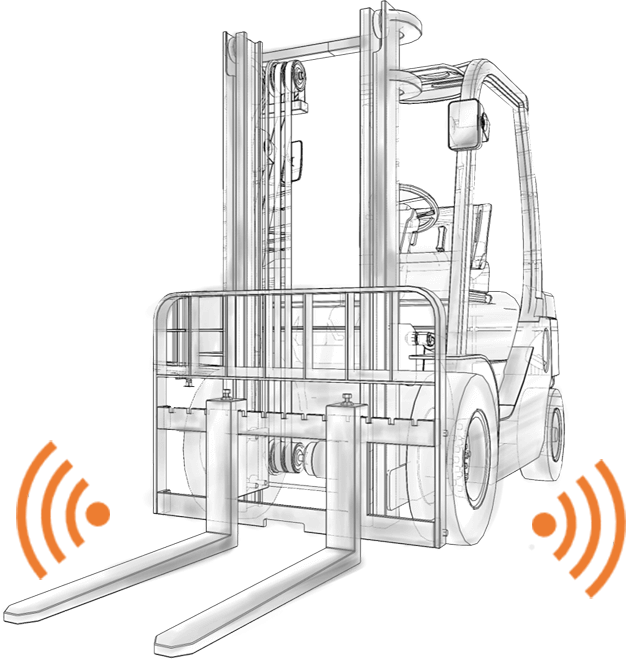

Safezone , a forklift safety, forklift fleet tracking, and collision warning system, is an IoT solution that dynamically adjusts real-time performance monitoring and safety needs in intralogistics operations according to environmental conditions, thus increasing occupational safety and efficiency.

Safezone is designed to prevent potential hazardous interactions and collisions between vehicles like heavy machinery, forklifts, reach trucks, milk-runs, and other constantly moving equipment within the facility, as well as interactions with equipment and personnel. This system has been developed to detect dangerous approaches of motor vehicles and pedestrians within the facility, visually and audibly warn operators, and slow down vehicles when necessary.

UWB

(Ultra-wideband)

Angular Approach Retreat and Direction Detection

Forklift Deceleration or Stopping

Easy Installation

Long Battery Life (Staff Tags)

Suitable for All Industries

(Wide Options)

How does the RTLS forklift safety and tracking system work?

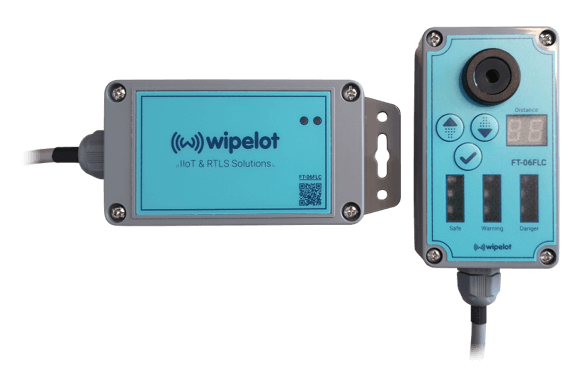

Safezone is a forklift safety system consisting of an easily deployable control unit and anchors with UWB (ultra-wideband) technology, designed to prevent vehicle collisions without causing any harm.

This system creates warning and danger zones around the forklift based on customizable distance settings. The system detects potential zone violations and generates audible and visual alerts for forklift operators, as well as vibration notifications for personnel tags.

Safezone Systems & Features

Safezone is the most comprehensive forklift safety and fleet tracking system that offers various scenario modules that can be customized according to the needs of businesses, the structure of the workspace, and regional conditions.

Safezone Basic

Easy-to-use plug-and-play that doesn't require RTLS infrastructure and boosts operational efficiency, personnel and equipment safety

Safezone Advanced

Ensures workplace health and safety in the face of physical variations while offering expanded safety and efficiency scenarios to achieve optimal productivity. It goes beyond basic scenarios to provide comprehensive occupational safety and enhanced operational efficiency.

Safezone is the most comprehensive forklift safety and fleet tracking system that offers various scenario modules that can be customized according to the needs of businesses, the structure of the workspace, and regional conditions.

Why Choose Safezone?

Enhance visibility, gain deeper insights for better operations

SYSTEM COMPONENTS

Collision Warning System

Equipment UWB TAG

Anchor & Gateway

Industrial UWB Anchor

Industrial UWB Gateway

EagleEye Motion

EagleEye Sense

Mobile Tags

Collar Type UWB Tag

Waist Type UWB Tag

Shoe Type UWB Tag

Equipment UWB Tag

Equipment UWB Tag

Equipment BLE Tag

Equipment BLE Tag

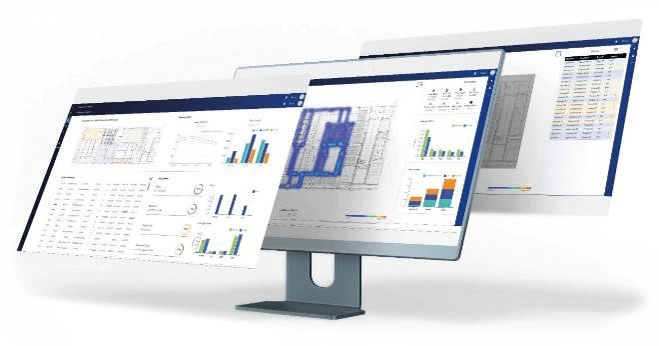

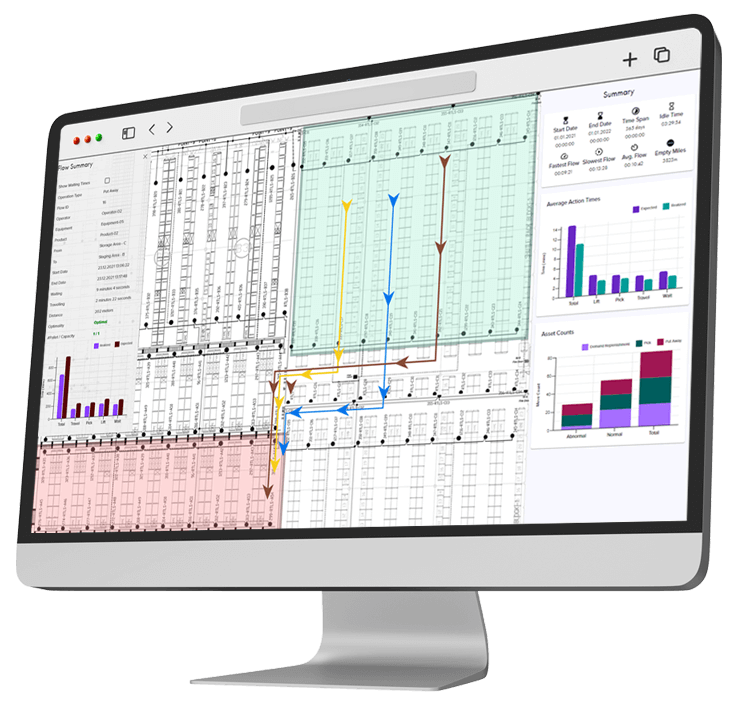

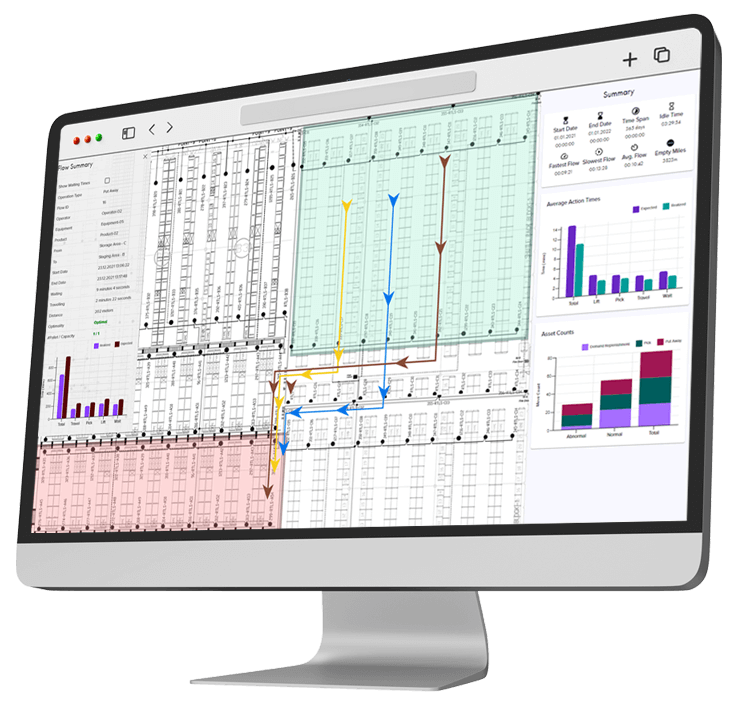

SOFTWARE

Wipelot's real-time location tracking software, Lotus, and the flow analysis and optimization module, Flow Analytics, elevate asset visibility and provide detailed insights into operational processes in facilities. This enables performance measurement for efficiency and helps mitigate potential risks in occupational safety.

Discover Related Success Stories

BSH - Safer Workplaces With Collision Warning System

The main purpose of the project was to develop and install a customized collision warning system at 3 of the manufacturing facilities of BSH in Çerkezköy, where the forklifts and pedestrians work closely together.

MONDI - Safer Environments For Assets And Workers

Using Safezone Collision Warning System, a safer environment was achieved without disrupting the workflow. Personnel injuries and material damages due to accidents were prevented. Thus, the workforce and financial losses were minimized.

Discover Related Blogs

Forklift Safety & Collision Avoidance System

In order to achieve the highest possible occupational safety in all work areas of forklifts, Wipelot has developed Safezone product range, a complete collision and warning system, using the UWB technology. Since each forklift operation environment is unique, Safezone family was designed as a solution that meets all requirements, with maximum flexibility that considers the operation environment, personnel and equipment structures.

Angular Forklift Safety System: Safezone EDGE

The Safezone EDGE Forklift Safety System goes beyond traditional 360° safety systems, offering an innovative solution with angular proximity and direction-sensing capabilities. These advanced algorithms enhance workplace safety by minimizing collision risks and boosting operational efficiency. This ensures not only the safety of employees but also more efficient and uninterrupted forklift operations.

Request Demokit

Let's work together to find the

best solution

for your business needs

Wipelot is a member of Omlox, the UWB Alliance, and the FiRa Consortium, which unite tech companies that manufacture their own hardware and software systems, with a focus on UWB technology solutions. Wipelot has been recognized as one of the fastest-growing tech companies on the TOBB 100 and Deloitte Technology Fast 50 lists. It has also received numerous awards for its industrial IoT projects in both Turkiye and abroad.

Discover More RTLS Systems

Lone Worker Safety

The Wipelot Lone Worker Safety System is an electronic occupational safety system that allows for real-time monitoring of the condition and position of workers working in hazardous settings, eliminating the need for communication equipment like as radios or phones.

Crane Positioning and Safety

Discover Wipelot’s Crane Positioning and Safety System – an advanced UWB-based workplace safety solution for collision prevention, load monitoring, and real-time crane tracking. Enhance operational efficiency and prevent workplace accidents in industrial environments.

Social Distance Tracking - SDS

The Social Distance Monitoring and Warning System developed by Wipelot helps establish a safe and isolated working environment in accordance with the social distance rules to combat the COVID-19 pandemic. The COVID-19 pandemic has directly affected 180 million people since the day it started and caused close to 4 million deaths.