RTLS Solutions in Warehouses

Wipelot's RTLS warehouse solutions provide a highly effective approach to enhance efficiency, productivity, and workplace safety in warehouse, supply chain, and port operations. The integration of RTLS into warehouse processes enables businesses to optimize inventory management, reduce errors, streamline order fulfillment, enhance employee safety, and ultimately improve overall operational efficiency.

Optimize asset performance, detect and prevent losses

Wipelot's real-time location systems-based analysis modules analyze the real-time asset data obtained from the field in-depth to optimize operational performances and provide data to identify and improve anomalies and losses.

Moreover, the advanced real-time location tracking technology allows you to learn about the performance and productivity of your employees. Provides statistics to predict future workload and optimize daily/weekly workload scheduling.

Monitor real-time performance in ports and warehouses

Detect abnormal flows

Increase efficiency by managing traffic optimization in your facility

Reduce idle time of assets

Manage workforce and resource usage

Reduce repetitious operations

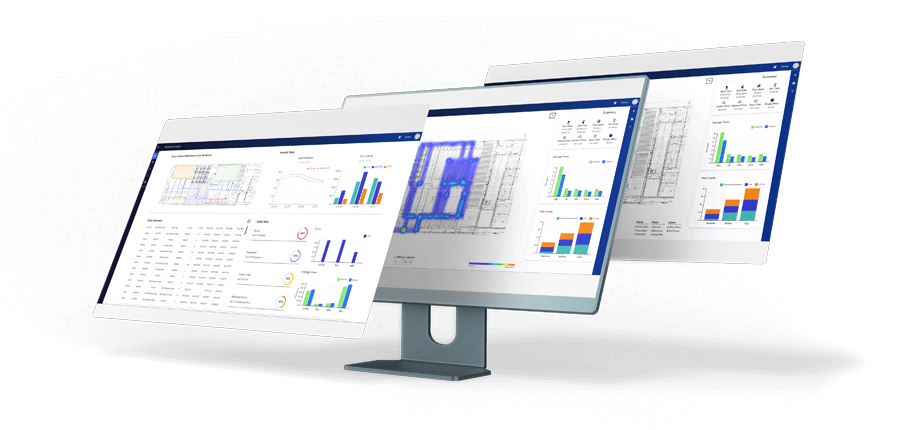

Data Analysis & AI Solutions

Wipelot's artificial intelligence-supported analysis modules developed for intralogistics enables end-to-end inventory tracking by maximizing operational visibility by analyzing real-time data (RTLS-WMS-ERP) obtained from various sources in the port or warehouse.

It saves time and money by optimizing material flow management and resource utilization with high-precision location information.

“With a high-precision location data and analysis module, you can optimize material flow management and resource utilization, saving time and money.”

2D & 3D Asset Tracking on Layout

Spaghetti Diagrams

Personnel and Equipment Performance Reports

Heatmap Reports

Footprint Reports

Emergency Reports

And many more...

RTLS MODULES

FORKLIFT AND MILKRUN VEHICLE TRACKING

Efficiently monitor routes and performance metrics, providing valuable data for optimization studies and generating daily heatmaps.

Personnel and Equipment Tracking

Monitor the location, condition, and performance of staff and equipment within the facility. Utilize an automatic scoring system to determine daily actual working times.

Stock-Container-Pallet Tracking

Real-time monitoring of container-pallet movements in and out, saving time in loading, unloading, and transporting semi-finished products to production. Optimize vehicle utilizing and shorten tour cycle times with precise measurement.

COLLISION WARNING AND WORKPLACE SAFETY

When forklifts, milkruns or similar vehicles approach each other more than a certain distance, certain areas and / or employees carrying personnel tags in the field, system warns employee or driver, and slowdown application is activated on vehicle

How do warehouses gain advantages from RTLS?

Data analytics

Workload prediction, dock analysis, dashboard, automated stock counting, real-time historical data.

Predictive maintenance

Increase overall motorized equipment efficiency & reduces or prevent failures.

Real-time asset, personnel and product tracking

Increase productivity & safety with high precision advanced indoor tracking system.

Higher employee productivity

Aiming to increase employee efficiency using real-time historical and instant field data.

Occupational safety

Determining the location of the emergency case with high accuracy.

Forklift tracking and collision warning system

Optimize warehouse traffic, idle times and avoid collisions with Safezone with real-time forklift tracking.

Discover Related Success Stories

BSH - Efficient Production Lines With RTLS

Wipelot Project Team carried out a discovery study at BSH's Çerkezköy facilities; and in order to get optimum performance from the production, the Team carried out a study to digitalize the process with real-time location tracking.

BORUSAN - Safer port operations for assets and workers

The instantaneous location tracking of the assets in Borusan Port, which is established on a total area of 465,000 m²

Safety and Efficiency in Food & Beverage with RTLS

One of Turkey's top dairy product manufacturers aimed to improve employee safety and operational efficiency by precisely tracking workforce locations using UWB-based active RFID technology. Overcoming challenges tied to metal tanks, the project seamlessly integrated with the existing personnel attendance control system, resulting in increased safety and enhanced operational processes.

Testimonials

We collaborated with Wipelot to improve the performance of our 112 forklifts in our operations at Vestel City. We were able to identify and minimize forklift productivity losses with Wipelot's own technology.

Wipelot's Safezone Forklift Tracking and Collision Warning System and Lone Worker Safety System applications have contributed to making our production facility safer for all staff and visitors.

At Borusan Port, we worked with Wipelot to improve work safety and reduce the need for labour. We have achieved very effective results in performance and safety by reducing the loss of labour due to filiation by up to 70%.

We chose the Wipelot solution as a platform. With the help of Wipelot, ESAN has achieved significant productivity in OSH strategies and processes

With Wipelot Iot, we increased the efficiency of equipment and vehicles in our facility.

Discover Related Blogs

Why do companies need Smart Warehouse Technology?

Warehouses were long managed manually, failing to meet modern demands and lacking sufficient safety measures—until the Industry 4.0 revolution. This new era introduced automation to manufacturing, warehousing, and distribution. Today, digital transformation in supply chains is crucial for company success.

Semi-finished product and stock tracking with RTLS

The real-time semi-finished product tracking system allows you to track all movements of every product, every vehicle, and every person in the facility using RFID technology. This increases efficiency and prevents time losses.

Real-time container and fleet tracking in ports

Expanding container port terminals are versatile mega-scale facilities, well-connected to road and rail networks. Their primary functions include container storage and shipment. With growing complexity and millions of tons in cargo capacity, these ports increasingly require real-time container tracking systems.

RTLS For Oil & Gas Industry

RTLS technology enhances safety and efficiency in the oil & gas industry. It enables real-time location tracking, monitoring of hazardous zones, and efficient equipment management. EagleEye, developed by Cisco and Wipelot, is a robust RTLS solution for challenging industrial conditions, optimizing safety in the oil & gas industry.

Forklift Telemetry for Fleet Management

Forklift telematics is a management system that monitors the performance, location, and operator behaviors of forklifts. This technology enhances operational efficiency, ensures job safety, predicts maintenance needs, and reduces costs.

Let's work together to find the

best solution

for your business needs

Wipelot is a member of Omlox, the UWB Alliance, and the FiRa Consortium, which unite tech companies that manufacture their own hardware and software systems, with a focus on UWB technology solutions. Wipelot has been recognized as one of the fastest-growing tech companies on the TOBB 100 and Deloitte Technology Fast 50 lists. It has also received numerous awards for its industrial IoT projects in both Turkiye and abroad.