Innovative RTLS solutions in manufacturing

The primary focus of industrial-scale manufacturing facilities is to prevent accidents and increase productivity despite the type, size, workforce, and equipment varying by sector. Wipelot's RTLS systems monitor, report, and provide real-time tracking of personnel, equipment, workspaces, and machines, offering advantages that enhance workplace safety and productivity. It digitizes complex production processes, making them faster and easier, thus saving time.

Increase productivity and workplace safety in manufacturing with RTLS

Wipelot's RTLS and IIoT modules offer significant benefits regarding safety and operational efficiency in the manufacturing industry. These technologies enable manufacturing companies to manage operations more effectively and gain competitiveness.

Boost Safety and Efficiency in Manufacturing with Wipelot's RTLS Modules.

Wipelot's RTLS and IIoT modules offer significant benefits regarding safety and operational efficiency in the manufacturing industry. These technologies enable manufacturing companies to manage operations more effectively and gain competitiveness.

Manufacturing RTLS Modules

Personnel Safety

This module enables real-time tracking of personnel and visitors within manufacturing facilities, raising safety standards and enhancing employee productivity. Facilities bolster safety measures by monitoring visitor numbers and identities in real-time, detecting falls and inactivity for swift response during emergencies. It tracks personnel's entry and exit times and determines violations in dangerous or restricted zones.

For More Information, Click Here

Lone Worker / Man Down Safety

This module, ensuring the safety of personnel working alone under hazardous conditions, shortens response times by transmitting incidents such as falls, immobility, and emergency calls to the system with precise location information. This provides an advantage in preventing loss of life.

For More Information, Click Here

Equipment Tracking

This module provides real-time precise location tracking for both motorized and non-motorized vehicles within the facilities, as well as maintenance and repair equipment. It monitors the operational hours of motorized service vehicles within the facility, offers historical route information, and generates reports on instances of speeding and driver habits. It tracks the engine status, calculates distance traveled, and assists in maintenance and fuel management. Additionally, it supports automatic vehicle-operator pairing and authorization, contributing to more efficient and secure operations.

For More Information, Click Here

Traffic Management & Collision Warning

Traffic optimization in manufacturing facilities contributes to increased operational efficiency. With its expandable structure, it creates a signalization network chain that can span kilometers, allowing for centralized monitoring and management. Additionally, it provides an adjustable safety zone around vehicles for equipment and personnel safety against collisions. Thanks to closed-circuit operation, it remains unaffected by general system failures.

For More Information, Click Here

Environmental Parameters & Meter Readings

This module instantaneously measures, records, evaluates, and generates alarms when parametric values are exceeded within the facility's environmental parameters. It operates in a closed-circuit mode via the Wipelot sensor network without the need for GSM networks or other external connections. Integration can be achieved with the existing sensors used within the facility. Gases such as carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), ammonia (NH3), hydrogen sulfide (H2S), oxygen (O2), ethylene (C2H4), and similar gases, as well as light and dust values, can be monitored by the system.

For More Information, Click Here

Cost reduction due to traffic improvement

50%

Increase in Shipping Speed

Reduction in Equipment-Related Work Accidents

90%Sustainable Efficiency with Data Analysis and Detailed Reporting

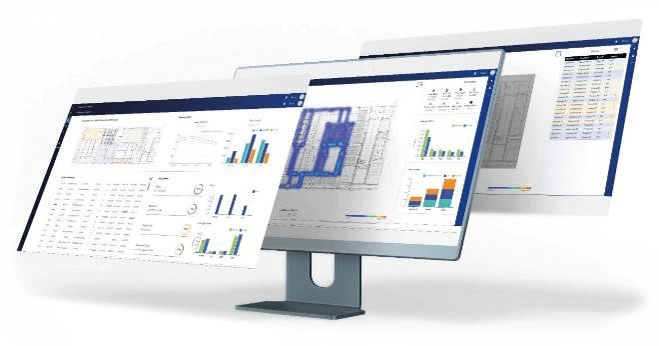

Wipelot's real-time location tracking software, Lotus, and the flow analysis and optimization module, Flow Analytics, elevate asset visibility and provide detailed insights into operational processes in facilities. This enables performance measurement for efficiency and helps mitigate potential risks in occupational safety.

Testimonials

We collaborated with Wipelot to improve the performance of our 112 forklifts in our operations at Vestel City. We were able to identify and minimize forklift productivity losses with Wipelot's own technology.

Wipelot's Safezone Forklift Tracking and Collision Warning System and Lone Worker Safety System applications have contributed to making our production facility safer for all staff and visitors.

At Borusan Port, we worked with Wipelot to improve work safety and reduce the need for labour. We have achieved very effective results in performance and safety by reducing the loss of labour due to filiation by up to 70%.

We chose the Wipelot solution as a platform. With the help of Wipelot, ESAN has achieved significant productivity in OSH strategies and processes

With Wipelot Iot, we increased the efficiency of equipment and vehicles in our facility.

Discover Related Success Stories

FORD OTOSAN - Award-Winner RFID Hybrid Project

Monitoring the locations of the crates in the facility & determining the duration of use.

Indoor Forklift Tracking and Performance Analyzing

The project's main goal is to analyze the operational performance of forklifts used in three different factories in Manisa as part of Vestel's digital transformation within the scope of Industry 4.0.

Safety and Efficiency in Food & Beverage with RTLS

One of Turkey's top dairy product manufacturers aimed to improve employee safety and operational efficiency by precisely tracking workforce locations using UWB-based active RFID technology. Overcoming challenges tied to metal tanks, the project seamlessly integrated with the existing personnel attendance control system, resulting in increased safety and enhanced operational processes.

Discover Related Blogs

How RFID Is Changing Work Safety Practices?

RFID is a member of the technology group called Automatic Identification and Data Capture (AIDC). Although the history of its use dates back to the World War Two, the first modern RFID patent was granted in 1973. Its intended use is basically recognizing objects, collecting data about the objects, and sharing this data with the relevant software systems.

Forklift Safety & Collision Avoidance System

In order to achieve the highest possible occupational safety in all work areas of forklifts, Wipelot has developed Safezone product range, a complete collision and warning system, using the UWB technology. Since each forklift operation environment is unique, Safezone family was designed as a solution that meets all requirements, with maximum flexibility that considers the operation environment, personnel and equipment structures.

Semi-finished product and stock tracking with RTLS

The real-time semi-finished product tracking system allows you to track all movements of every product, every vehicle, and every person in the facility using RFID technology. This increases efficiency and prevents time losses.

How RTLS Transforms the Automotive Industry

This article emphasizes the transformative role of digital technologies, especially RFID and RTLS, in the automotive industry's production processes. These technologies address the critical challenges of reducing manual processes and enhancing automation. RFID and RTLS solutions offer real-time tracking, transparency, and accuracy in managing materials and vehicles, leading to significant improvements in efficiency and productivity.

Let's work together to find the

best solution

for your business needs

Wipelot is a member of Omlox, the UWB Alliance, and the FiRa Consortium, which unite tech companies that manufacture their own hardware and software systems, with a focus on UWB technology solutions. Wipelot has been recognized as one of the fastest-growing tech companies on the TOBB 100 and Deloitte Technology Fast 50 lists. It has also received numerous awards for its industrial IoT projects in both Turkiye and abroad.