Real Time Asset Tracking and Analysis With RTLS

Efficiency, safety, and sustainability have become core priorities for modern industries. Asset Tracking and Monitoring Systems play a crucial role in achieving these goals. Wipelot's RTLS (Real-Time Location System) solutions enable businesses to monitor their physical resources in real time and optimize their operations effectively.

What Does “Asset” Mean for Facilities?

In industrial facilities, the term "asset" refers to any physical or digital resource critical to operational processes. This includes everything from production equipment to personnel and inventory. These assets play an essential role in maintaining the continuity of production processes, ensuring workplace safety, and meeting efficiency goals.

What Is Asset Tracking?

Asset tracking is the process of monitoring the location and status of a business's valuable resources in real time. This technology covers a wide range of applications, from personnel and motorized equipment to inventory and environmental conditions. RTLS (Real-Time Location System) uses technologies such as ultra-wideband (UWB), Bluetooth Low Energy (BLE), GPS, and hybrid systems to provide highly accurate data for this purpose.

- Production Efficiency: Identifies operational bottlenecks and optimizes resource utilization.

- Workplace Safety: Reduces risks by ensuring the safety of personnel and equipment.

- Cost Control: Minimizes costs by quickly locating lost or misused assets.

Indoor and Outdoor Asset Tracking with RTLS

Indoor and outdoor asset tracking offers innovative solutions to meet the growing operational demands of modern industries. Indoor asset tracking ensures precise monitoring of equipment, personnel, and inventory within facilities. Commonly used in industries such as manufacturing plants, logistics centers, and healthcare, these systems enhance operational efficiency and elevate workplace safety to a higher level.

Outdoor asset tracking, on the other hand, is designed for real-time monitoring of vehicles, equipment, and personnel across expansive outdoor areas. This technology supports smooth operational processes in sectors such as mining, manufacturing, logistics, healthcare, and aviation. It allows for route optimization, minimizes the risk of losses, and ensures workplace safety.

Hybrid asset tracking combines indoor and outdoor systems to provide scalable solutions for facilities with increasing size, capacity, and complexity. As facilities grow, the rising number of equipment and personnel demands more effective management of operational processes. (click for related usecase) Hybrid systems integrate both indoor and outdoor asset tracking into a single infrastructure, offering seamless operation. Commonly implemented in sectors like logistics, aviation, manufacturing, and ports, these systems digitize both indoor and outdoor workflows. They ensure error-free inventory management, prevent operational disruptions, and reduce costs through real-time data analytics.

Wipelot's RTLS solutions address these needs, delivering a robust tool that enhances both safety and efficiency.

Wipelot's Asset Tracking Solutions for Industries

Manufacturing

- Real-time tracking of employees and equipment on production lines.

- Optimizing maintenance processes to ensure efficient equipment operation.

- Monitoring the movement of semi-finished products.

- Improving inventory management and preventing losses.

- Tracking employee locations, statuses, and analyzing performance.

- Ensuring the safety of lone workers.

- Increasing efficiency through route and traffic optimization for carrier vehicles like milk-run systems.

Logistics and Warehousing

- Tracking the locations of warehouse vehicles like forklifts and providing data-driven reporting and optimization.

- Efficient use of warehouse space, improved inventory management, and analysis of employee locations and statuses.

- Accelerating loading and unloading processes.

- Implementing forklift telemetry systems.

Mining

- Ensuring the safety of workers and equipment in both underground and surface operations.

- Preventing accidents in high-risk areas.

- Automating tasks and processes to boost productivity.

- Optimizing traffic flow within mining sites.

- Enabling automated scale operations.

- Real-time tracking of maintenance and repair processes.

Healthcare

- Real-time tracking of staff, patients, newborns, and critical medical equipment.

- Enabling rapid response in emergencies.

- Monitoring the location, status, and inventory of ambulance equipment.

- Enhancing operational efficiency in healthcare facilities.

Aviation

- Tracking the locations of baggage, cargo, and ground service equipment.

- Monitoring visitor movements and restricted area access.

- Ensuring the safety of motorized equipment in apron areas.

- Improving overall operational efficiency.

Reporting and Data Analysis Reduce Costs

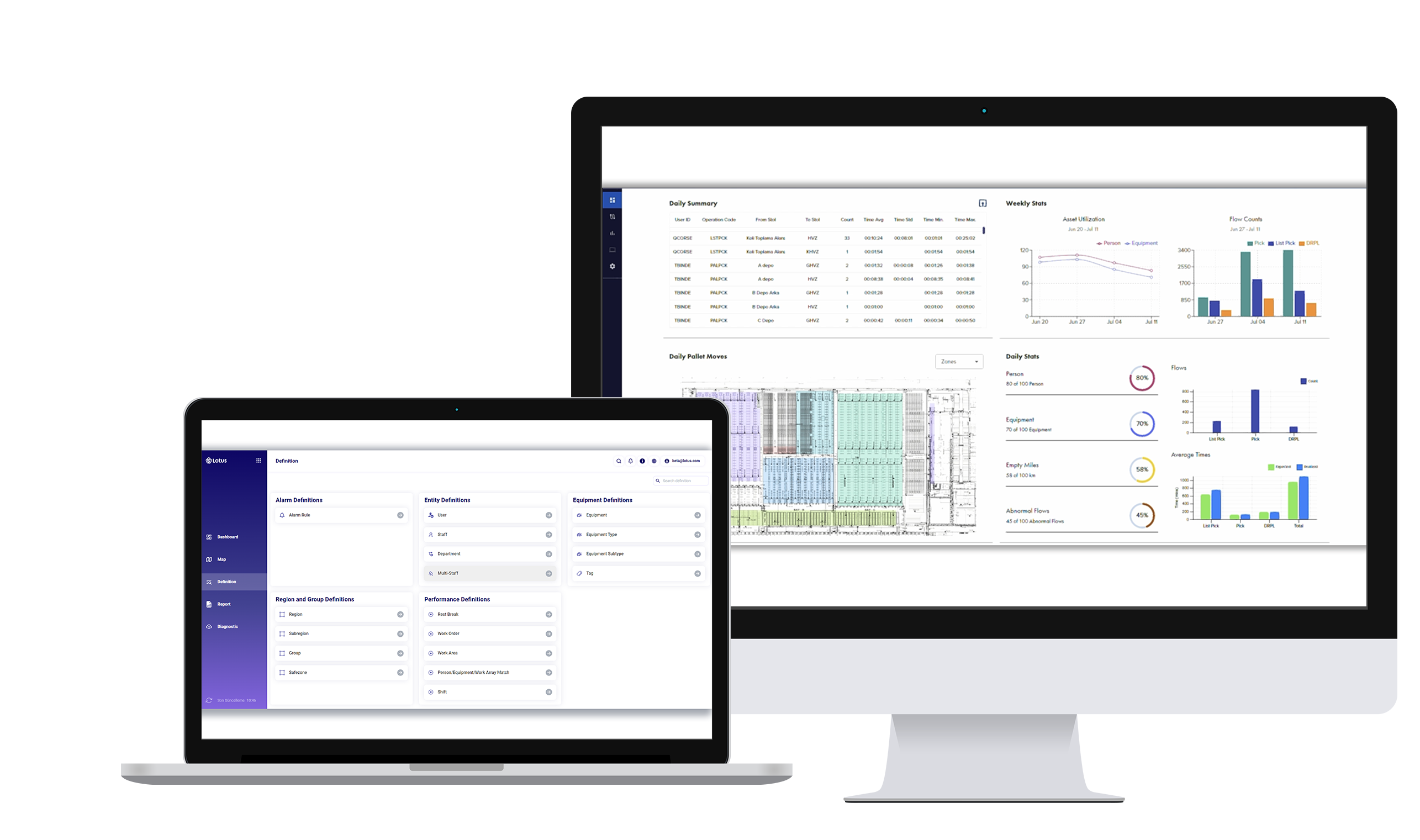

Reporting and data analysis transform the information provided by asset tracking systems into actionable insights, offering businesses essential support in their strategic decision-making processes. Real-time data collection allows for a detailed analysis of the performance of inventory, equipment, and personnel. This enables businesses to identify and eliminate operational bottlenecks, improve resource utilization, and reduce costs. LOTUS, the reporting and analysis software at the core of Wipelot's RTLS solutions, plays a critical role in enhancing efficiency and ensuring workplace safety in industrial processes.

- Prevents losses through error-free inventory management.

- Optimizes processes with performance analyses.

- Identifies and resolves operational bottlenecks.

- Enables data-driven decisions to enhance employee and equipment safety.

- Facilitates quick intervention and planning through real-time reporting.

- Reduces costs and improves resource efficiency.

FAQs for Decision Makers

- How does real-time asset tracking improve operational efficiency in industrial environments?

- Real-time asset tracking identifies operational bottlenecks and optimizes the use of resources. By minimizing search times and improving workflow automation, it enhances overall process efficiency across sectors like manufacturing, logistics, and mining.

- What are the key benefits of using RTLS for workplace safety?

- RTLS ensures the safety of both personnel and equipment by providing real-time visibility. It enables rapid response in emergencies, reduces risks in high-risk zones, and ensures lone worker safety through continuous monitoring.

- Can RTLS track both indoor and outdoor assets effectively?

- Yes, RTLS solutions support both indoor and outdoor asset tracking. Indoor systems monitor equipment and personnel within facilities, while outdoor systems track vehicles and staff across wide areas using technologies like UWB, BLE, and GPS.

- How does Wipelot's RTLS solution contribute to cost reduction?

- Wipelot’s RTLS system reduces costs by preventing asset losses, eliminating operational bottlenecks, and enabling data-driven decisions through detailed reporting and analytics provided by the LOTUS software platform.

- What industries can benefit from hybrid asset tracking systems?

- Hybrid systems are ideal for industries like logistics, aviation, and manufacturing. They offer seamless tracking across indoor and outdoor environments, improve inventory accuracy, and help manage increasing operational complexity as facilities scale.

Asset Tracking: A Key to Efficiency, Safety, and Sustainability

In modern industries, asset tracking is not just a tool for monitoring but also a critical enabler for process optimization, improving workplace safety, and achieving sustainability goals. Wipelot's RTLS solutions offer real-time tracking, detailed analysis, and efficient reporting, making every stage of operational processes safer and more efficient. These systems not only provide benefits such as error-free inventory management, bottleneck elimination, and cost reduction but also support strategic decision-making for the future.

The robust analysis and reporting infrastructure integrated with asset tracking not only addresses today's business needs but also contributes to achieving long-term sustainability goals. By combining innovative RTLS technology with advanced analytics, Wipelot helps businesses build a safer, more efficient, and more sustainable future.

Discover Wipelot's innovative RTLS solutions today to make your business processes safer, more efficient, and more sustainable. Contact us for more information!

For more details about Wipelot's RTLS systems, visit our RTLS page.

Learn more about real-time location technologies by reading this article.