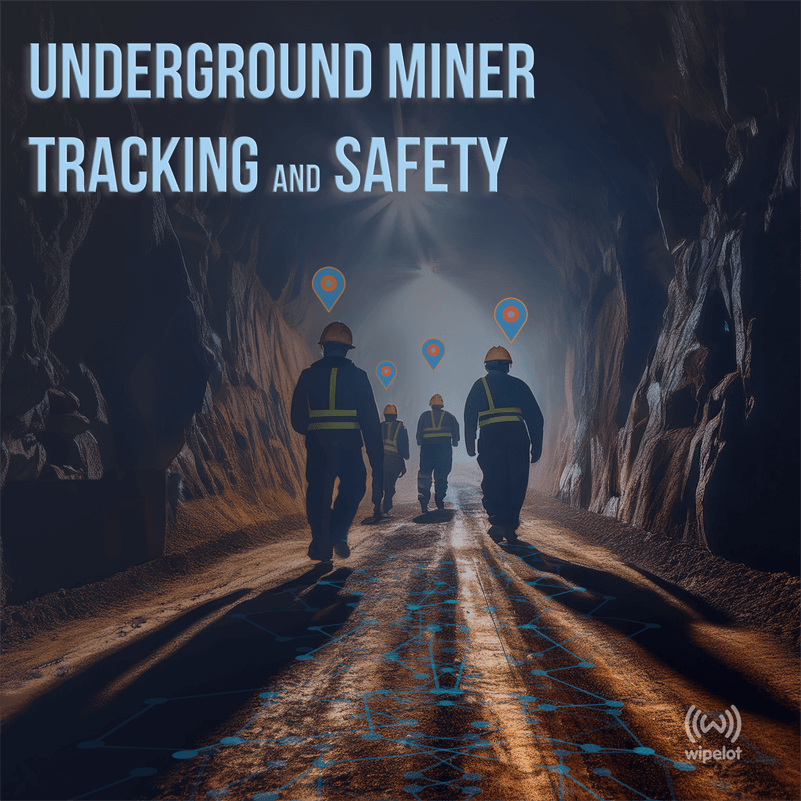

Mine Worker Positioning and Safety with RTLS

Mining environments are hazardous due to their natural structure and challenging working conditions. Risks such as narrow tunnels, limited visibility, sudden cave-ins, and gas leaks make these areas dangerous for workers. Under these harsh conditions, it is crucial to monitor the locations and statuses of personnel in real-time. Swift response during emergencies enhances personnel safety and improves the efficiency of rescue operations.

What is an Underground Personnel Tracking System?

Underground mining presents significant risks due to its hazardous working conditions. An underground miner safety system addresses these dangers by prioritizing personnel safety, enabling swift responses in emergencies, and improving overall occupational safety. The Wipelot RTLS system ensures safety by accurately tracking personnel positions and statuses with sub-meter precision. This capability allows rapid and precise detection of personnel in emergencies, resulting in timely and effective intervention.

The Wipelot underground miner tracking system provides essential safety solutions for all mining operations.

Wipelot Underground Miner Tracking System

The Wipelot underground miner tracking system delivers essential safety solutions for mining operations. Its expandable and modular infrastructure allows businesses to customize the system according to their needs. This flexibility lets managers implement cost-effective and long-term safety solutions.

Personnel-Contractor Status Monitoring and Emergency Alarm System

The system continuously monitors the locations and conditions of personnel and contractor workers in underground mines. It triggers alarms immediately in emergencies. It automatically detects hazardous situations, such as workers remaining immobile in a horizontal position or falling, and reports them to emergency response teams, ensuring quick and effective intervention.

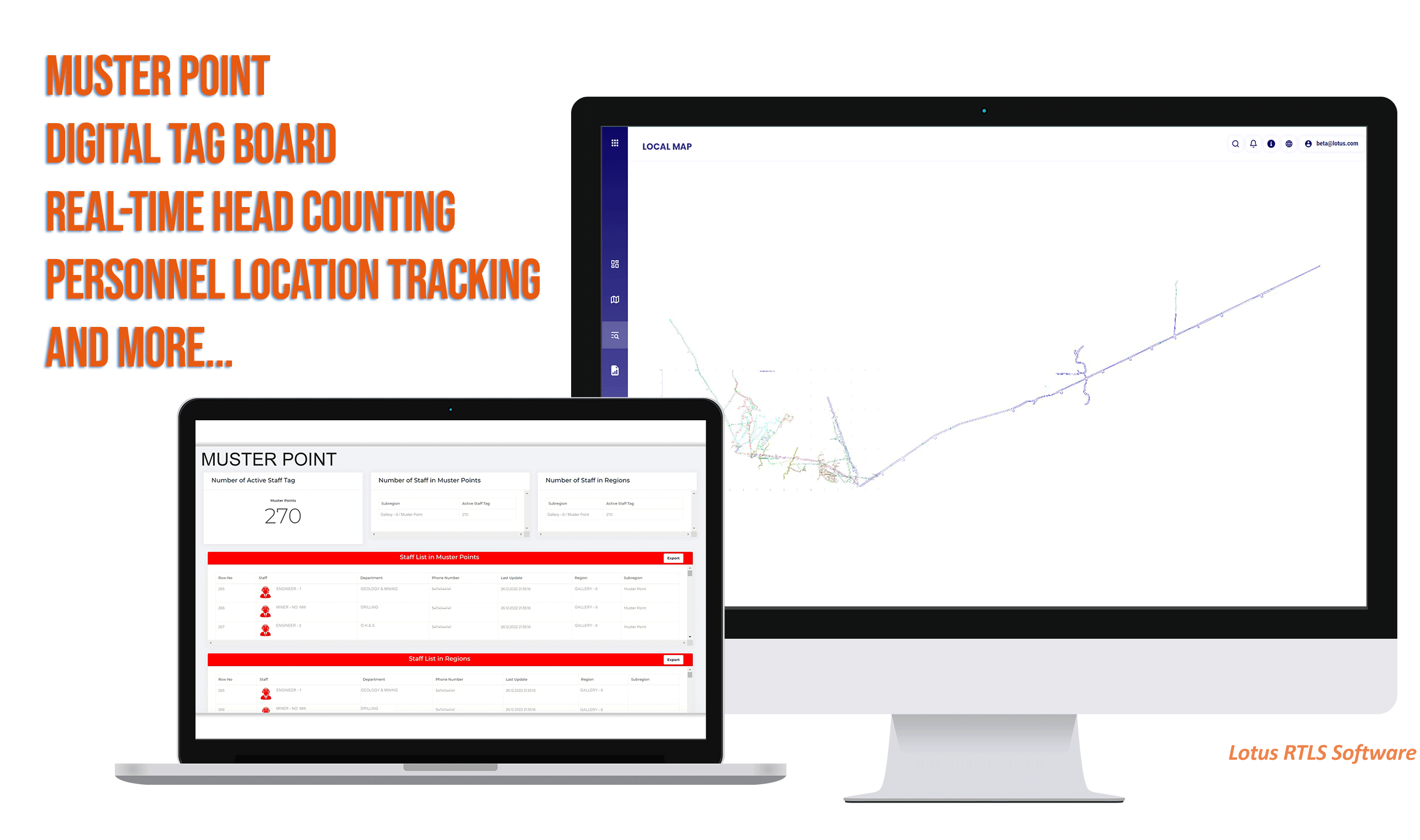

Digital Tag Board

The digital tag board visually displays the real-time status and locations of personnel and equipment at the mine site. This feature makes it easier to manage all operations on-site and supports rapid intervention during emergencies.

Muster Point Management

In an emergency, it is critical to lead employees safely to muster points. The Wipelot RTLS-based underground miner tracking system automatically counts personnel at assembly points, providing complete and accurate information. This feature improves emergency management processes and ensures the safe evacuation of all employees.

Restricted Zone (GeoFence) Creation

To ensure personnel safety, managers must define and restrict access to hazardous or unauthorized areas in mines. These areas may include galleries under construction or places at risk of flooding, electrical leakage, or collapse. The Wipelot RTLS system manages access to hazardous zones, prevents unauthorized personnel from entering or approaching these areas, logs any potential violations, and sends warnings to those violating the rules, enhancing workplace safety.

Easy Integration with Personnel Attendance Control System

The Wipelot RTLS system integrates with the Personnel Attendance Control System to monitor employee entry and exit movements and track shift durations. This integration improves work efficiency and employee safety by accurately tracking the working hours of personnel and contractors and optimizing workforce planning with precise time management.

Key Benefits of an Award-Winning Smart Mining Solution

Wipelot Smart Mining solutions offer several key benefits, including improved production efficiency, increased ore extraction, and enhanced occupational safety. By integrating RTLS (Real-Time Location Systems), IIoT (Industrial Internet of Things), and AI (Artificial Intelligence) technologies, these solutions provide full visibility, control, analysis, optimization, and reporting in mining operations.

Enhanced Occupational Safety

- Real-time tracking of personnel location and status tracking.

- Provides rapid intervention and rescue capabilities in emergencies.

- Supports safety standards by monitoring restricted zone violations and social distancing.

Operational Efficiency

- Optimizes work processes by monitoring the performance of equipment and personnel.

- Facilitates effective management of operations with task and production planning screens.

- Improves traffic flow and work area utilization with vehicle footprint and heat map reports.

Cost Reduction

- Reduces fuel consumption and maintenance costs by analyzing driver behavior and speed limits.

- Lowers operational costs through data analysis and optimization support.

Environmental Monitoring and Management

- Tracks and manages environmental risks with extensometer and fire alarm reports.

- Continuously monitors environmental conditions to increase energy efficiency.

Flexibility and Adaptability

- You can customize the positioning accuracy and system settings according to specific needs and demands.

- The system supports various business requirements with both local and cloud-based server options.

Legal Compliance

- The system complies with occupational health and safety regulations and meets the legal requirements for mining operations.

Frequently Asked Questions about Underground Miner Tracking and Safety

- What is an underground miner tracking system and how does it work?

- An underground miner tracking system is a safety solution that uses Real-Time Location Systems (RTLS) to monitor workers in underground environments. Wipelot’s system tracks the location and status of each miner with high precision, detects emergencies like falls or immobility, and enables immediate intervention.

- How does Wipelot’s RTLS system improve emergency response in underground mines?

- Wipelot’s RTLS solution improves emergency response by automatically detecting critical events, such as a miner lying motionless or entering restricted zones. It sends instant alerts to rescue teams, reducing response time and increasing the chance of a successful intervention.

- Can Wipelot’s miner tracking system be customized for different mining operations?

- Yes. The system is modular and scalable, allowing mines to customize positioning accuracy, server options (local or cloud), and integration with existing attendance systems or mine management platforms.

- What are the main safety benefits of using Wipelot’s underground tracking solution?

- The key benefits include real-time personnel tracking, automatic alarm triggers, muster point attendance counting, restricted zone management, and full visibility into personnel movements—ensuring regulatory compliance and improved safety.

- Does the system help mining companies meet legal safety regulations?

- Yes. Wipelot’s system complies with occupational health and safety standards by accurately documenting worker locations, managing access to hazardous areas, and enabling fast emergency response—fulfilling legal safety requirements in underground operations.

Safety is always the top priority in underground mining. Wipelot's RTLS-based smart mining solutions use cutting-edge technologies to ensure the highest level of safety for personnel and equipment. These systems feature real-time tracking, emergency alarm systems, and tag boards, helping to maintain occupational safety standards while improving operational efficiency. Wipelot RTLS offers sustainable and cost-effective safety solutions.

Contact us now to ensure maximum safety and efficiency in your mining operations!