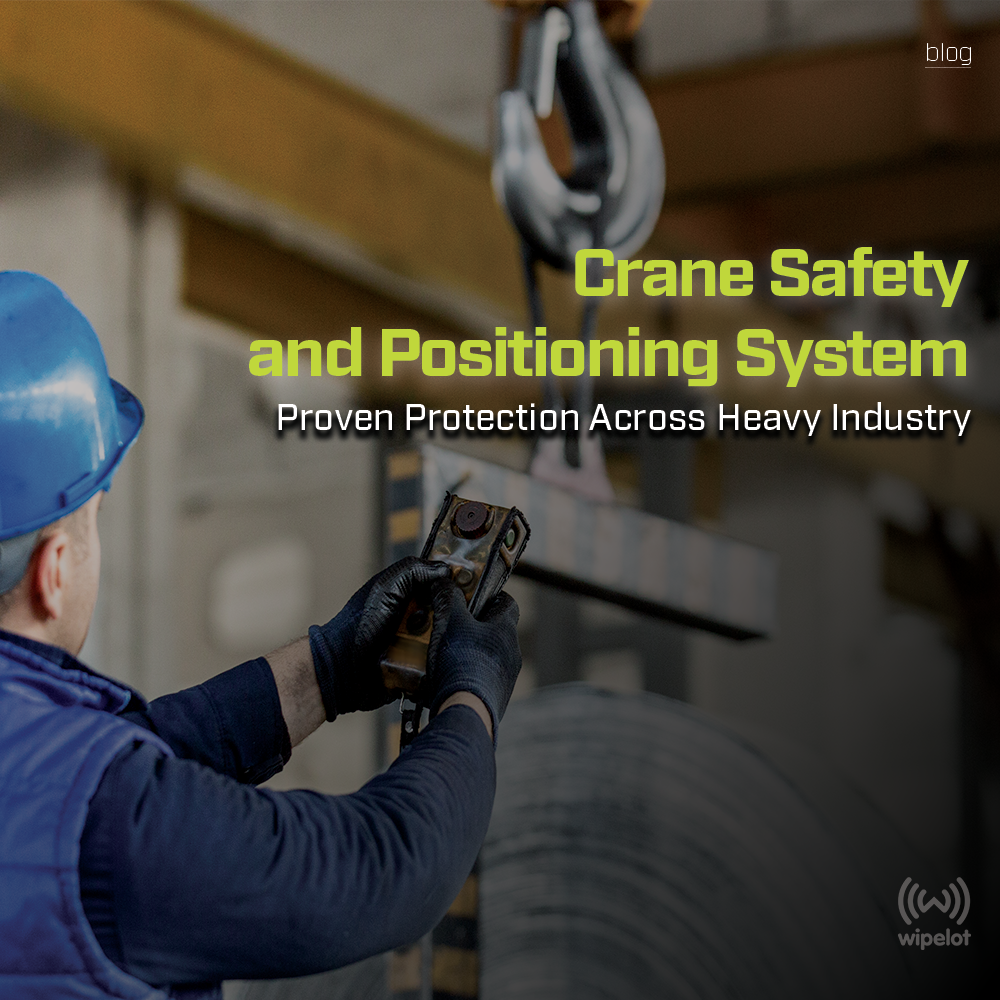

Crane Safety RTLS: Protecting Workers and Assets in Industrial Environments

Overhead cranes are the workhorses of modern industry. From construction sites and steel mills to shipyards and automotive plants, these powerful machines lift, move, and position loads that can weigh dozens of tons. They're essential to productivity — but they're also among the most dangerous equipment in any industrial facility.

The numbers tell a stark story. According to OSHA, crane-related incidents cause an average of 44 fatalities and more than 8,000 disabling injuries annually in the United States alone. Approximately 45% of crane accidents involve contact with power lines or electrical sources, while collisions between crane components and facility structures, equipment, or personnel account for a significant portion of remaining incidents. Each accident carries devastating human cost, alongside operational disruptions, regulatory penalties, and financial liability that can cripple operations for weeks or months.

The challenge is compounded by the nature of crane operations themselves. Operators work from limited vantage points, often unable to see the full path of the load or hook. Blind spots are inherent to the equipment. Spatial awareness becomes guesswork when moving multi-ton loads through complex facilities with narrow clearances, overhead obstructions, and active work zones. Traditional methods — spotters, painted floor markings, manual measurements — help, but they depend entirely on human vigilance in environments where distractions, fatigue, and communication failures are ever-present risks.

That's where Wipelot comes in.

From Guesswork to Precision Protection

Wipelot has engineered an intelligent Overhead Crane Collision Warning Solution that eliminates uncertainty from crane operations. Using advanced sensor technology and real-time mapping, our system creates a protective digital envelope around moving cranes, loads, and facility infrastructure — detecting potential collisions before they occur and alerting operators with time to respond.

Through precision sensors mounted on crane structures and integrated with facility mapping software, Wipelot's system continuously monitors the position of crane hooks, loads, trolleys, and bridges in three-dimensional space. The technology calculates collision trajectories in real time, accounting for load swing, crane movement speed, and proximity to walls, columns, equipment, and other cranes operating in shared airspace.

When the system detects a potential collision, it responds instantly: visual alerts appear on operator displays, showing exactly where the hazard exists; auditory warnings escalate as proximity decreases, ensuring operators cannot miss critical notifications; and automated slow-down protocols can engage, reducing crane speed in high-risk zones to give operators additional reaction time.

Proven Protection Across Heavy Industry

Steel mills, shipyards, automotive manufacturing plants, and construction sites have deployed Wipelot's crane collision warning technology with transformative results. The system prevents crane-to-wall and crane-to-structure collisions that cause costly damage and dangerous situations, eliminates crane-to-crane conflicts in facilities where multiple overhead systems share operational space, protects personnel working beneath or near crane paths by alerting operators to ground-level activity, and reduces load swing incidents by providing real-time feedback on pendulum motion and clearance margins.

Why Choose Wipelot Crane Collision Warning

- Three-dimensional awareness – Complete monitoring covers every axis of crane movement, from hook height to bridge position and trolley travel.

- Intelligent prediction – Advanced algorithms calculate collision risk based on movement vectors, load dynamics, and facility geometry — not just static proximity.

- Multi-crane coordination – In facilities with multiple overhead cranes, the system manages shared airspace, preventing conflicts before they develop.

- Operator-focused design – Intuitive alerts and displays provide actionable information without overwhelming operators or disrupting workflow.

- Retrofit-ready – Compatible with existing crane systems across manufacturers and facility types, enabling rapid deployment without equipment replacement.

Technology That Protects People, Assets, and Production

In industries where overhead cranes are indispensable, safety cannot be left to chance. With Wipelot, industrial facilities gain more than a warning system — they gain an intelligent guardian that sees the unseen, calculates the incalculable, and transforms high-risk crane operations into controlled, predictable processes where safety and productivity work in harmony.

Because in heavy industry, protecting workers and assets isn't just about avoiding accidents — it's about creating environments where precision, confidence, and safety define every lift, every move, every day.

FAQ About Crane Safety & Positioning

- Q: What is Wipelot's Overhead Crane Collision Warning Solution?

- A: It is an RTLS-powered system that uses 2D and 3D mapping and precision sensors to create a protective digital envelope around cranes and their loads. It detects and prevents potential collisions with structures, personnel, or other cranes in real-time.

- Q: How does the Wipelot system prevent crane accidents?

- A: The system continuously monitors crane component positions and calculates real-time collision trajectories, considering variables like load swing. It instantly triggers visual and auditory warnings, and can initiate automated slow-down protocols in high-risk zones.

- Q: What unique advantage does Wipelot offer over traditional crane safety methods?

- A: Unlike reliance on human spotters or markings, Wipelot eliminates blind spots using intelligent 3D awareness and predictive algorithms. This allows the system to manage shared airspace and calculate risk based on dynamic movement vectors, not just static proximity.

- Q: Can Wipelot's collision system be installed on existing cranes?

- A: Yes. The technology is designed to be retrofit-ready and compatible with existing crane systems across various manufacturers and facility types, ensuring rapid deployment without requiring new equipment.

- Q: What are the primary benefits of using Wipelot’s system?

- A: The main benefits are eliminating crane-to-structure and crane-to-crane collisions, safeguarding ground-level personnel, and reducing equipment damage and operational downtime by up to 30% by creating controlled, predictable lifting processes.

- Ready to eliminate crane collision risks in your facility? Discover how Wipelot's safety solutions can protect your operations and workforce.