How RTLS Transforms the Automotive Industry

RTLS Technology in the Automotive Industry

When we think of productivity-focused industries, the automotive sector comes first. To stay competitive, automotive manufacturers aim to increase their efficiency every year. To manage efficiency gains, the automotive industry integrates many strategies and technologies into every production stage to achieve sustainable productivity improvements. Therefore, where modern manufacturing processes stand today requires high standards not only in speed and efficiency but also in terms of workplace safety and quality control.

Efficiency-Oriented Approach in the Automotive Industry

The automotive industry has undergone significant transformation over the years, particularly with the advent of Industry 4.0, which necessitated the integration of digitalization and automation. Real-Time Location Systems (RTLS) have emerged as crucial in optimizing production processes, enhancing efficiency, and improving workplace safety within the automotive sector amidst this transformation.

RTLS Technology and KPIs

Automotive manufacturers use a variety of Key Performance Indicators (KPIs) to improve efficiency and quality. These metrics include OEE (Overall Equipment Effectiveness), OTIF (On-Time in Full Delivery), inventory turnover, and production speed. These KPIs are critical tools for assessing and improving the effectiveness of production processes. For example, optimizing assembly line processes to speed up human labor tasks by just one second can result in annual efficiency gains of up to 5%.

RTLS technology is one of the key technologies used to manage and improve these KPIs. Real-time tracking of vehicles and equipment, increasing personnel productivity, optimizing material flow, data integration and analysis, and lowering maintenance and labor costs are just a few of the many ways that RTLS technology is transforming the automotive industry.

How has RTLS changed the automotive industry?

RTLS technology has transformed the automotive industry by rewriting the rules with its innovative features and benefits. Automotive manufacturers use real-time location data to meet regulatory requirements, identify assembly line risks or errors, and improve offline area management. Furthermore, it improves real-time traffic management for intralogistics fleets, increasing overall supply chain and factory efficiency. Analyzing location data over time helps to optimize facility layouts and reduce unnecessary material handling.

The Role of RTLS in Efficiency

RTLS technology provides numerous opportunities to improve efficiency in the automotive industry. This technology offers several key benefits, including optimizing production processes, improving material flow, and increasing workforce productivity.

Optimizing Processes with Vehicle and Equipment Tracking

- Real-Time Tracking: RTLS allows for real-time monitoring of the location of vehicles and equipment, ensuring that they are in the right place at the right time on the production line. This improves efficiency in production processes, resulting in smoother and faster operations.

- Reducing Idle Times: Tracking forklifts and other motorized equipment reduces unnecessary idle time and productivity losses. This not only reduces production line halts but also ensures that business processes run continuously.

- Route and Traffic Optimisation: RTLS helps to plan the quickest routes for transporting materials within production or assembly lines by vehicles such as forklifts, milk runs, and tuggers. This improves intralogistics processes by preventing delays caused by traffic congestion, resulting in smoother operations.

Material Flow Optimization

- Identifying Bottlenecks: RTLS technology identifies bottlenecks and optimizes material flow to minimize delays and interruptions on production lines.

- Increasing Resource Utilization: Minimizing unnecessary travel distances and errors maximizes resource utilization. This means that production processes require less energy and time due to optimized material movements.

- Tracking Material Flow: Tracking material flow ensures timely and accurate delivery to the production line, minimizing disruptions.

Data Integration and Analysis

- ERP and WMS Integration: RTLS integrates with ERP and WMS systems to collect and analyze data from production processes. These analyses increase operational efficiency while also identifying areas for improvement.

- AI and Data Analytics: Artificial intelligence and data analytics improve processes like workload forecasting, flow optimization, and asset performance monitoring. This has the potential to increase production line efficiency over time significantly.

Reducing Maintenance and Labor Costs

- Preventive Maintenance: Real-time monitoring of equipment enables early detection of maintenance requirements and prevents unplanned breakdowns. This reduces maintenance and labor costs, ensuring that the production line runs continuously and smoothly.

Optimization in Assembly Lines

- Improving Operational Processes: RTLS optimizes operational processes in assembly lines, shortening operation times and speeding up overall production.

- High-Precision Location Tracking: In dynamic assembly lines where every second counts, RTLS provides high-precision location data, which improves operational and assembly times.

- Part and Component Tracking: Passive RFID tags can track each part and component used in assembly lines. This ensures that parts are used in the proper order and at the appropriate locations throughout the assembly process.

- Assembly Sequence Management: RFID technology manages assembly sequences and verifies step accuracy, ensuring quality assurance throughout the process.

- Automatic Time Recording: Enables accurate tracking of working hours for personnel across multiple workstations, facilitating performance monitoring.

(to see: Award winner hybrid RTLS project)

Increased Workplace Safety

RTLS technology also offers effective solutions for improving workplace safety. One of the primary benefits of this technology is that it ensures employee and equipment safety, prevents workplace accidents, and allows for rapid intervention in emergencies.

Collision Prevention Systems

- Blind Spot Detection and Automatic Deceleration: RTLS-based collision prevention systems improve workplace safety by preventing forklifts from colliding with employees, robots, or large die molds. These systems have features including blind spot detection, automatic deceleration, and stopping.

- Speed Control: Zone-based speed control limits forklifts and other motorized vehicles to specific speeds. This ensures the safety of vehicle occupants, surrounding employees, and robotic systems.

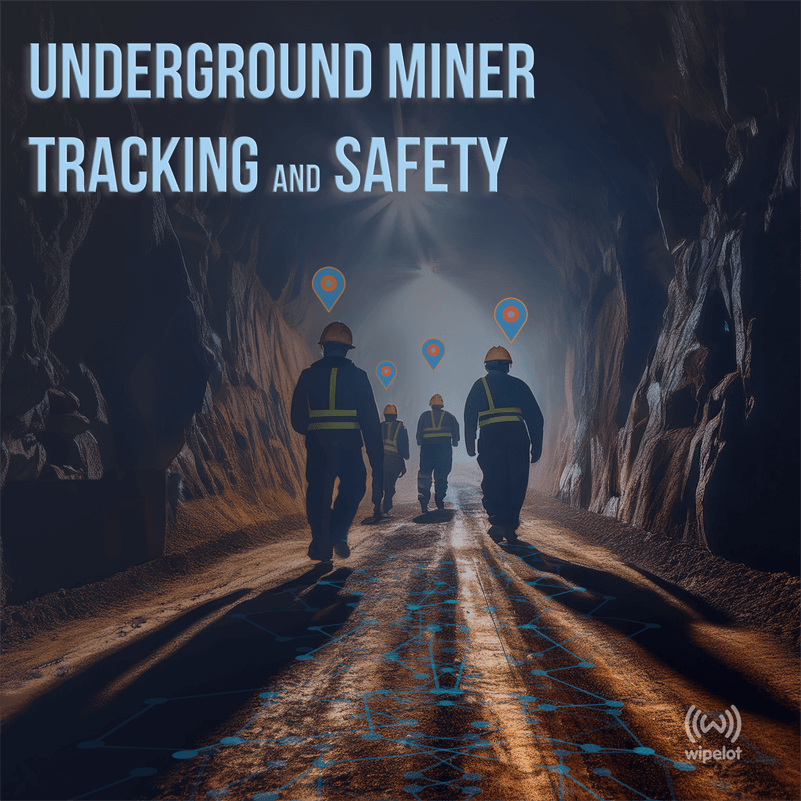

Personnel Tracking and Safety

- Employee Safety: Real-time tracking ensures lone worker safety by allowing for immediate intervention in emergency calls and assistance requests. In assembly or production lines where humans must work alongside robots, precise tracking of their location and positions is performed with centimeter-level accuracy. Warning scenarios are in place in the event of a distance violation.

- Social Distance Monitoring: Warning systems are activated in the event of a violation of social distancing rules, ensuring that the distance between employees remains constant. This feature is especially important for maintaining workplace health and safety during pandemics.

- Quick Response: RTLS pinpoints employees' exact location during emergencies, allowing for quick response. In an alarm situation, relevant personnel receive audible and visual alerts via SMS and email. This ensures a faster and more effective emergency response process while also providing employees with a safe working environment.

- Authorized Personnel Usage: RTLS allows only authorized personnel to access specific equipment or areas. This avoids accidents and damages that could result from unauthorized use. Preventing unauthorized access to equipment aids in maintaining safety standards.

F.A.Q. about RTLS and the Automotive Industry

How does RTLS technology increase efficiency in the automotive industry?

RTLS technology enhances efficiency in the automotive sector by enabling real-time tracking of cars and equipment, ensuring they are in the right place at the right time on the assembly line. This reduces unnecessary idle times, empty miles, and productivity losses, making processes more efficient and streamlined. Additionally, it leads to significant overall efficiency improvements through procedures such as material flow optimization, route planning, and bottleneck detection.

How do RFID and RTLS solutions enhance workplace safety?

RFID and RTLS systems enhance workplace safety in several ways. For example, they include collision avoidance systems to prevent forklifts and other vehicles from colliding with personnel or equipment. Additionally, they feature real-time tracking of lone workers and alarm systems to detect violations of social distancing norms. These systems also enable faster response in emergencies and help prevent unauthorized access. Overall, RFID and RTLS solutions significantly reduce workplace accidents and safety violations.

What are the key challenges in the assembly line?

The assembly line in the automotive sector faces several key challenges, including time management, parts and component tracking, workforce efficiency, and quality control. To tackle these issues, digital transformation solutions such as RTLS technology can be employed to streamline operations, track parts and components accurately, boost workforce efficiency, and enhance quality control processes.

How do RFID and RTLS technologies benefit the automotive industry?

RFID and RTLS technologies offer significant benefits to the automotive industry by enabling real-time tracking, transparency, and accuracy in the management of materials and vehicles. These technologies optimize production processes, reduce errors, and support better forecasting, decision-making, and process consistency. As a result, they improve quality, enhance operational efficiency, and contribute to higher profitability in the automotive sector. Wipelot's experience and expertise ensure the successful implementation of these technologies.

How does RTLS support material flow optimization in automotive plants?

RTLS identifies bottlenecks, tracks material movement, and reduces unnecessary travel by optimizing routing, thereby ensuring timely and accurate delivery of materials to production lines.For more information, please visit our website or contact our experts. Get in touch with us to improve your efficiency using RTLS technology!