Forklift Safety & Collision Avoidance System

Truly safe working areas are now possible for the forklifts and personnel

Since its invention, the forklift has been an integral part of the industry, yet bringing with it a constant risk of accidents. Although there have been many attempts and solutions to remedy this situation for years, the forklift accidents remain as one of the most important safety risks in industry. The total weight of the vehicle and its load, combined with its speed, creates significant hazards for all the assets on its way.

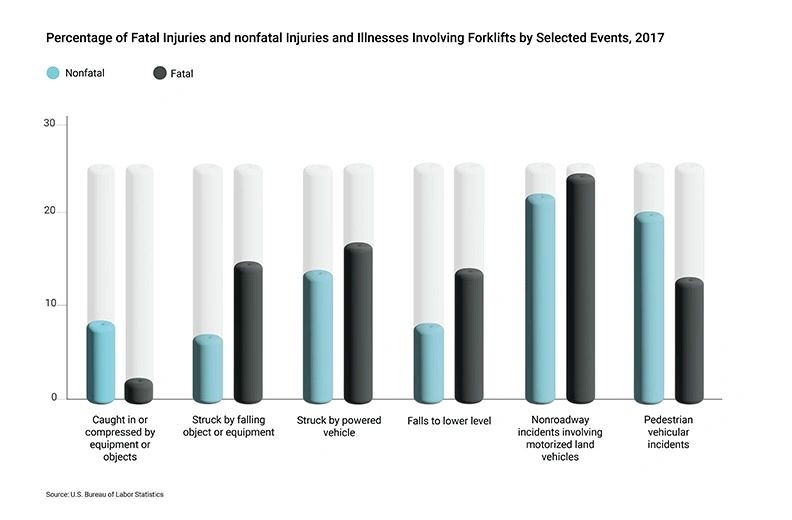

The forklift accidents generally lead to very grave results, and the number of fatal accidents is considerable. U.S. Bureau of Labor Statistics indicated that the forklifts get involved in 7500 accidents on average annually, and led to 75 to 94 fatal accidents between 2011 and 2017. Furthermore, the forklift accidents cause more than 20 days’ absence on average, and it has to be noted that this is the highest rate for occupational injuries.

As well as injuries and fatalities, the forklift accidents result in financial, legal and criminal sanctions for companies and enterprises. According to U.S. Bureau of Labor Statistics, the sanctions amount to $13,000 on average per incident and to approximately $126,000 for recurring incidents. For example, nearly 12,000 accidents involving forklifts occur in Germany annually, and more than 1,000 accidents causing serious injuries occur in Great Britain annually.

REAL TIME LOCATION AND UWB TECHNOLOGY

As it is the case for every field, the technological advancements dedicated to solve this problem are now in our lives. With the current achievements of wireless technology, it is now possible to determine the real time locations of the forklifts, personnel and equipment, and to take real time precautions depending on location data.

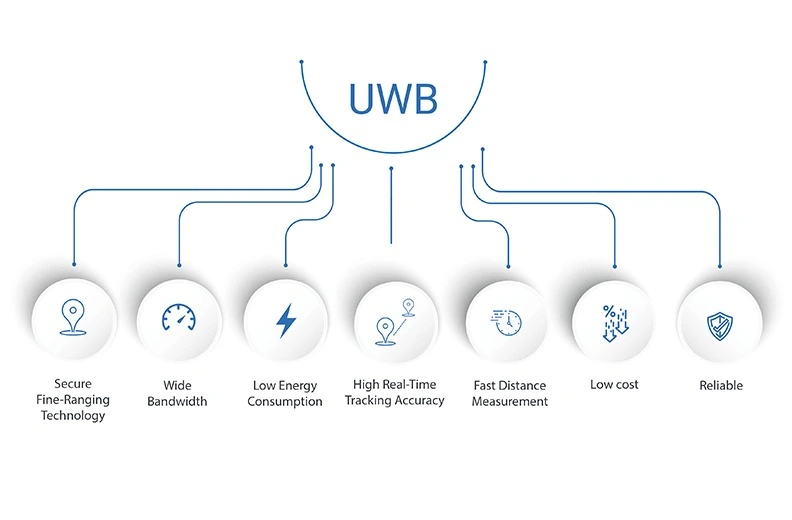

UWB (Ultra Wide Band) is a short range, wireless data transmission protocol designed to operate on a high bandwidth at a very high frequency, and it is preferred more for location applications compared to Bluetooth or Wi-Fi. This protocol is based on IEEE 802.15.4a/z standard, which was developed for use in precision location applications. This protocol is given priority over other systems for real time precision location tracking systems due to its distinguishing advantages such as energy efficiency, low delay time, resilience against interference signals and compatibility with power supplied by mobile device batteries.

SAFEZONE COLLISION WARNING SYSTEM

In order to achieve the highest possible occupational safety in all work areas of forklifts, Wipelot has developed Safezone product range, a complete collision and warning system, using the UWB technology. Since each forklift operation environment is unique, Safezone family was designed as a solution that meets all requirements, with maximum flexibility that considers the operation environment, personnel and equipment structures. This new solution is distinguished from many similar safety systems thanks to its latest UWB technology with 20 cm precision, which does not require infrastructure modifications, is easy to install and have low initial cost; and it completely meets all the usual safety requirements of warehouses and plants such as forklift-forklift, forklift-personnel and blind spots.

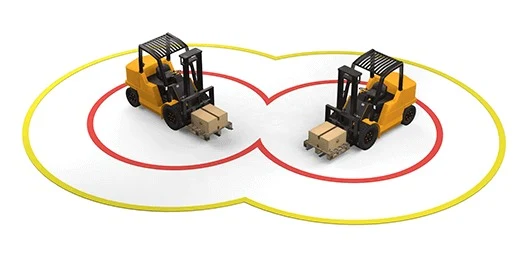

Forklift - Forklift Interaction

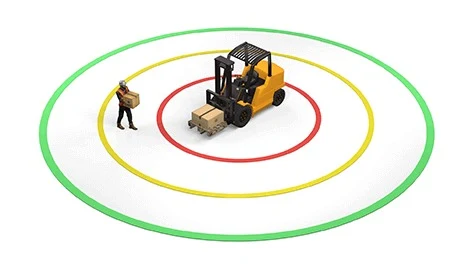

Forklift - Personel Interaction

How does Safezone work?

In a nutshell, the Safezone system operates by creating two different safety zone levels of 360 degrees around the moving forklift, namely warning zone and danger zone. The radii of these warning zones can be easily set according to the requirements of the working areas. In case a forklift or a personnel is detected inside the warning zone, the alarm center in front of the operator alerts the operator with a yellow visual warning and an audible warning. If supported by the forklift, the speed may also be decreased automatically inside this zone. In the case that the detected forklift or personnel is inside the danger zone, the alarm center in front of the operator issues an audible warning and the red visual warning, and the forklift can be stopped. Thanks to the low signal delay of UWB, this collision warning system allows the necessary measures to be taken as soon as possible.

The Pedestrian Personnel is Also Safe with Safezone

Safezone collision warning system uses personnel tags for protecting the employees while they are in the vicinity of an operating forklift. These tags can be carried around the neck and on the waist, or they can be attached on the occupational safety footwear of the personnel as required.

The forklifts detect the tags on the personnel as they detect the other forklifts, and contribute significantly to the elimination of work accidents that may result in injuries or graver consequences by providing the same alerts and protection including the complete halting of the forklift.

SAFEZONE ADVANCED WITH ADVANCED EFFICIENCY OPTIONS

As well as basic occupational safety requirements, Safezone collision warning system developed by Wipelot also offers efficiency-enhancing modules for the physical differences and requirements in the field. Due to the difference of the plants and operation processes, different implementation scenarios are required in different work areas without compromising on the occupational safety of the forklifts and personnel.

Safezone Advanced has additional modules to ensure maximum efficiency with the scenarios developed for such physical differences and requirements.

Silent Zone

This is a solution developed for areas separated with barriers or away from pedestrian and vehicle traffic, thus without the possibility of physical accidents. Even if a personnel or a forklift inside the silent zone interacts with a forklift in the vicinity of this zone, the warning scenarios are not activated and unnecessary slow-downs are avoided, thus ensuring an uninterrupted operation process.

Adaptive Zone

Safezone operates according to the warning and danger zone distances defined for the interactions of the forklifts and pedestrians. However, at some zones in the work area, it may be necessary to implement scenarios different from the defined distances. In such cases, the forklifts and pedestrians that enter the area defined as adaptive zone work according to the warning and danger zone parameters applicable for this zone.

Aisle Interaction

The personnel and forklifts working in the aisles between the shelves at the warehouses and plants do not create an accident risk even if they are within warning distances of each other. Safezone Advanced detects the personnel and vehicles working in such areas and deactivates the warning scenarios, thus contributing to an uninterrupted operation process. The safety warnings may be activated when multiple forklifts work in an aisle, while a forklift working in the adjacent aisle is not affected by these safety warnings. Safezone Advanced operates with the RTLS Infrastructure for the aisles requiring special scenarios. In such areas, automatic slow-down may be defined for the vehicles, or the distances for the warning and danger zones may be changed automatically.

Safer Working Areas with Safezone

Safezone collision warning system developed by Wipelot is used by many large industrial companies for the safety requirements at different levels at the plants, without compromising on the efficiency. The system is practical since it does not require cabling infrastructure, and it is effective with respect to hardware costs. With Wipelot’s RTLS software Lotus, all configurations can be carried out remotely, the zones can be defined according to the geometrical shape of the work area, and all the necessary reports are produced.

The forklifts have been indispensable since the invention of logistics operations, but they remain in our lives as being responsible for a large part of serious occupational accidents until today. Safezone is a reliable wireless occupational health and safety platform, with its modules that protect the forklifts operators, employees and assets, and enhance the work activities and increase efficiency. Considering the high costs that the forklift accidents cause for the enterprises, Safezone may pay off its investment cost by preventing a single accident.

Also discover the angular forklift safety solution: Safezone EDGE